Quality

Quality is one of Farmalabor key strengths, due to the professionalism of the Farmalabor staff and state-of-the-art equipment and machinery. Laboratory staff has a perfect knowledge in the validation of analitycal methods and cleaning procedure, equipment approval, periodic environmental checks in production areas and stability studies carried out on finished products to guarantee long term quality for the stock. Faberfarma is a devision of Farmalabor: "the only company dealing with APIs repackaging equipped with internal laboratories for chemical analysis, microbiology and pharmaceutical techniques".

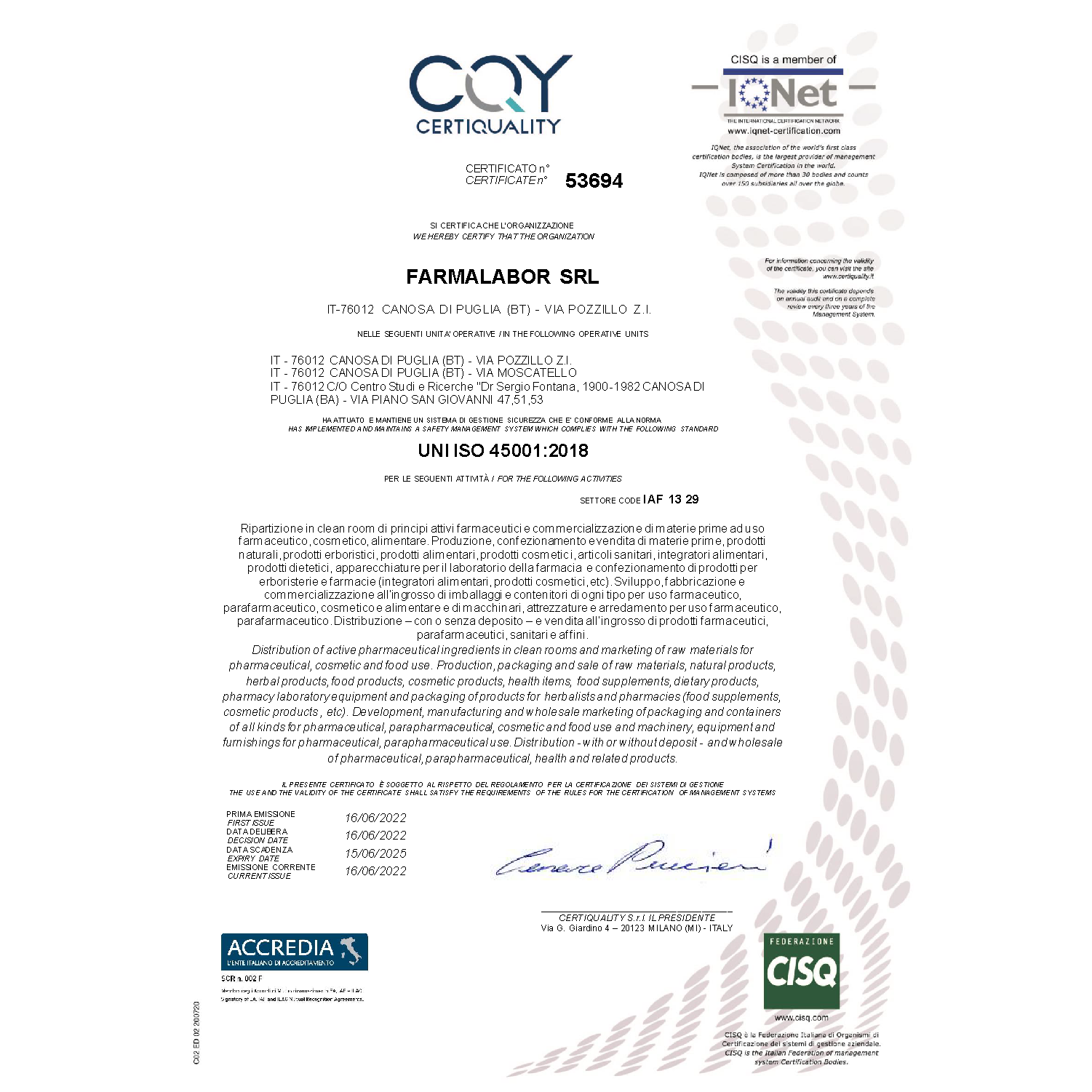

Quality control laboratory operates along with GMP (Good Manufacturing Practice) and ISO requirements in order to assure the full compliance and the highest quality of all raw materials. Quality Assurance department operates autonomously in order to assure the full compliance with the requirements of GMP, ISO 9001, ISO14001 and ISO45001 in all company sectors (production, purchase, quality control, final product, sales and post-sales assistance). In accordance with Italian Legislative Decree 219/06, Farmalabor is authorized by AIFA (the Italian Medicines Agency) as Importer, Repacker, Labeller, Quality controller and Allocator and Releaser of Active Pharmaceutical Ingredients batch. The GMP (Good Manufacturing Practice) certification guarantees, nationwide and Europe-wide, the application of the “good manufacturing standards” assuring a high quality in the purchase, breakdown, re-labeling, quality control and batch release of all raw materials. The achievement of GMP certification is a paramount way to state worldwide the excellence of quality “Made in Italy”. Farmalabor is the company authorised by AIFA for the breakdown and repackaging of the greatest number of Active Pharmaceutical Ingredients (APIs). Farmalabor. Quality made in Italy.